SYSTEMS AND LINES

STERILISATION AND

ASEPTIC PACKAGING SYSTEMS

Treatments for sterilisation and aseptic packaging of fruit juices, creams and concentrates, tomatoes, carrots, peppers, preserving the organoleptic characteristics and specific to each type of product.

Products that can be processed with our sterilisation and aseptic packaging plants

We have experience in the sterilisation of creams and fruit juices since the 1960s.

Based on our experience, we acquired and developed the necessary know-how, launching our new sterilisation and aseptic filling system in 1980

Our sterilisation system for concentrated products with high viscosity and the aseptic filling of pre-sterilised flexible bags made from multilayer high barrier laminates, has evolved and extended to liquid, pasty products, also with diced tomato and pieces with preserving liquid.

characteristics of the system

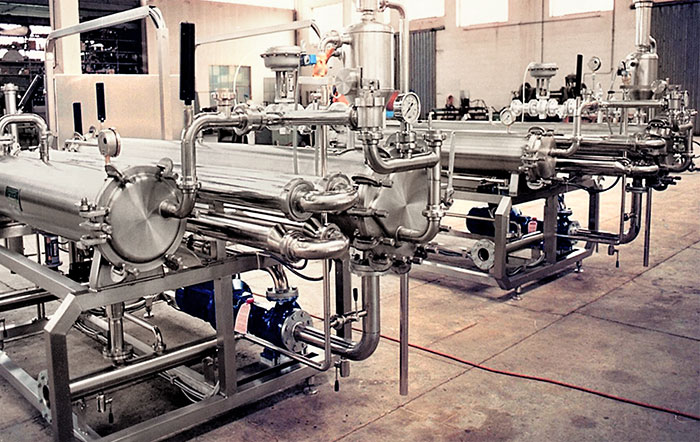

Regarding the rheological characteristics of the products to be processed, we supply a range of steriliser consisting of heat exchangers that can be:

- plate

- tube bundle or multitube

- lined tube or single-tube

- tube-in-tube formed by four suitably sized concentric tubes.

Simple, safe systems that are easy to operate and maintain

The line is completed with our exclusive aseptic filling machines for flexible bags with a range of models for different production capacities and degrees of automation.

Our systems feature simple and intuitive operation, complete automation and above all the total guarantee of success of the system.

Our experience in this difficult area has been built in the field, so it is absolutely distinctive and recognisable.

We supply unique solution that simplify operation and make the operator task easier.

ADVANTAGES AND SPECIFIC FEATURES

AUTOMATION Controlled by

a PLC, they are programmed to carry out the work cycle completely independently.

They are accompanied by process and safety sensors.

The operation is completely automatic and all the phases in the operating cycle are performed without the intervention of the operator.

A digital recorder stores the critical process parameters.

The systems are INDUSTRY 4.0 READY and can be integrated into existing factory management systems.

VERSATILITY

The operating cycle is highly customisable and adaptable to the type of product to be processed.

The programming is entered on the touch screen control panel.

EASY TO USE

The operators are guided by the information that appears on the operator panel.

Each alarm and warning also reports the most common cause and informs the operator of the corrective action to be taken.

SAFETY

Our diced tomato aseptic filling lines are accompanied equipped with process and safety sensors.

All systems are equipped with the necessary safety systems according to the requirements of the European Directive and are CE marked.

the machines used in these lines