SYSTEMS AND LINES

Fruit cream PRODUCTION LINES

With hot and cold extraction

Production of high quality fruit cream and purée with hot and cold extraction

HOT EXTRACTION TECHNOLOGY

COLD EXTRACTION TECHNOLOGY

"Hot extraction technology" is the main and most used technology for the production of fruit purées, creams or cremogenates.

"Cold extraction technology" is used for processing red skinnedfruit.

HOT EXTRACTION TECHNOLOGY

The main and most used technology for the production of fruit Purees, Creams or Cremogenates, is the so-called “Hot Extraction Technology“, which is used for all varieties of fruit grown in temperate climates.

This technology is used to produce the best quality with maximum yield.

Our fruit creams production lines are designed with the utmost attention to the hygiene and health problems of the processing process and to eliminate product oxidation.

Maintains the organoleptic characteristics of the fruit for a product of the highest quality

Enzymatic inactivation is performed after shredding the product in an oxygen-free environment, in a high thermal efficiency heat exchanger that controls the heat treatment time, and inactivates all the oxidative enzymes before they can do harm.

Maintenance at the inactivation temperature for a set time and subsequent partial cooling at a temperature suitable to minimise the loss of aromas during the subsequent cream extraction.

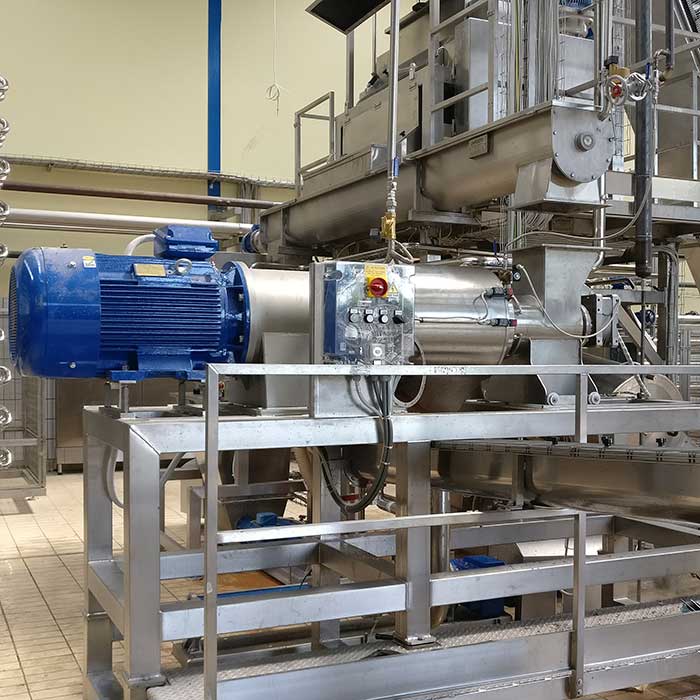

Our exclusive Dual-stage centrifugal extractor Mod. “Tornado” specially designed for processing fruit, extracts in a few seconds with high yields of the finished product.

Equipped with devices to adjust the degree of extraction, depending on the different types of fruit, it is easy to inspect and allows the drum to be changed in a few seconds; equipped with automatic programmable washing.

The cream is then transferred to the deaerator for gas extraction by vacuum pulverisation, the extracted gases are then condensed to recover the aromas.

The system can be completely automatic and managed by a PLC system with operator panel, HMI, touch-screen used

- to manage the process

- the control parameters

- control all the variables in the field

- display of alarms in real time

- the level values

- temperature

- pressure

- flow and speed of the motors

- display the diagnostics of any faults.

COLD EXTRACTION TECHNOLOGY

The cold extraction technology is used for the processing of red-skinned fruit and is intended to prevent the passage of anthocyanins, contained in the skin of red fruits, responsible for the brown colouring of the pulp, into the pulp extracted.

The colour is transferred by hot contact, therefore it is necessary to separate the skin from the rest of the fruit before the heat treatment.

This technology is mainly used for processing apples with red skin and partly for red peaches.

Avoid the passage of anthocyanins

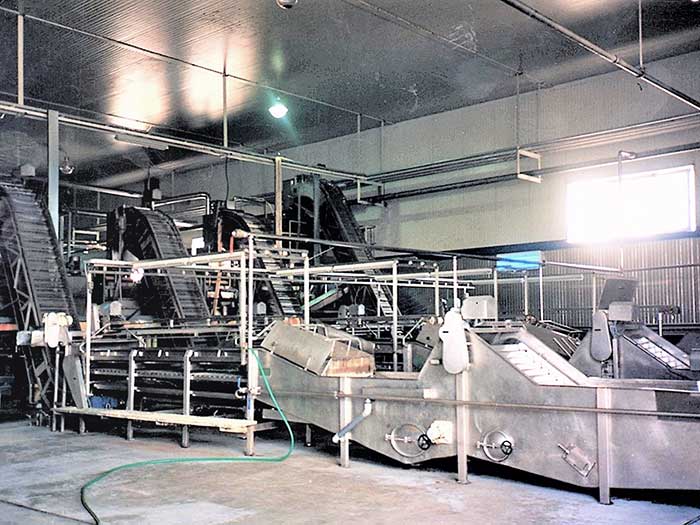

Apples or pitted peach pulp are introduced directly into our exclusive monobloc extractor, Mod. ”Meltemi“, composed of a special crusher, installed directly at the infeed to the centrifugal extractor in which they are separated, cold, and the skins from the rest of the fruit.

The whole operation takes place in an anaerobic atmosphere and in a short time. The pulp is instantly transferred to the “Rapid” preheater, with high thermal efficiency, for hot enzymatic inactivation and then sent to the centrifugal finisher for the extraction of the cream.

All other operations are carried out as in the hot technology.

ADVANTAGES AND SPECIFIC FEATURES

AUTOMATION Controlled by

a PLC, they are programmed to carry out the work cycle completely independently.

They are accompanied by process and safety sensors.

The operation is completely automatic and all the phases in the operating cycle are performed without the intervention of the operator.

A digital recorder stores the critical process parameters.

These systems are INDUSTRY 4.0 READY and can be integrated into existing factory management systems.

VERSATILITY

The operating cycle is highly customisable and adaptable to the type of product to be processed.

The programming is entered on the touch screen control panel.

EASY TO USE

The operators are guided by the information that appears on the operator panel.

Each alarm and warning also reports the most common cause and informs the operator of the corrective action to be taken.

SAFETY

Our fruit cream production lines with hot and cold technology are accompanied by process and safety sensors.

All systems are equipped with the necessary safety systems according to the requirements of the European Directive and are CE marked.

the machines used in these lines

TORNADO • Centrifugal extractor

MELTEMI • Centrifugal extractor

Elevators and conveyors

Defoliator

Pitting machines

Sorting tables

Pulpers

Deaerators with aroma recovery