MACHINES

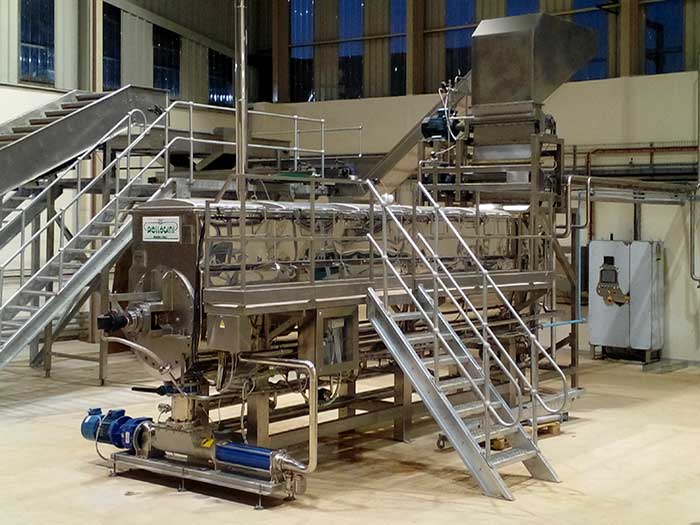

Thermobreak Trough cookers

Cook and defrost with high capacity, hygiene, versatility, robustness.

Trough cookers are used for cooking fruit pulp, carrots, beetroot and defrosting IQF or shredded and diced fruit.

ADVANTAGES AND SPECIFIC FEATURES

VERSATILITY

Can be used with any vegetable or fruit type, possibility to exclude or include the various heating systems as needed.

AUTOMATION

In the most advanced versions, it is controlled by a PLC with touch screen operator panel and is completely automatic. The operating parameters such as speed and temperatures are fully programmable.

EASY TO USE

The loading and unloading operations can be carried out manually or in combination with an automated basket handling

RELIABILITY

Designed for durability and low maintenance. The surfaces in contact with the product are rounded and mirror polished.

PROCESS CONTROL

The different heating systems can be activated independently and simultaneously and, together with the variable rotation speed of the trough, allow maximum precision in controlling and modulating the heat treatment.

SAFETY

They are equipped with all the safety systems necessary to comply with the safety requirements required by European directives and comply with the CE marking.

PED-certified pressure equipment

Designed for durability and low maintenance

TROUGH COOKERS

Our trough cookers are made in AISI 304 stainless steel

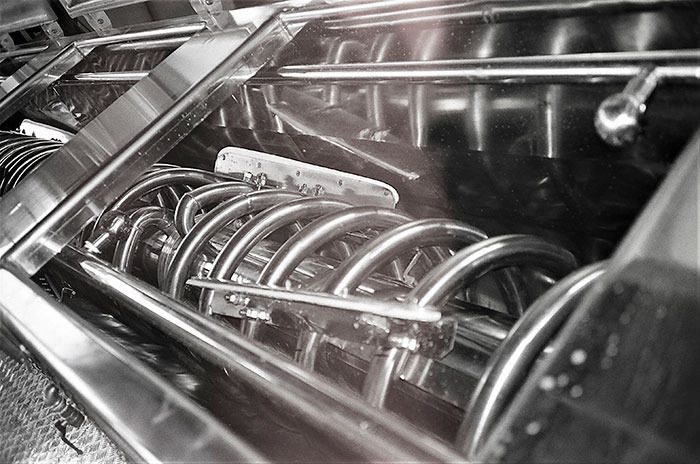

As required, the machine can have the following steam heating systems:

– cavity heating

– direct injection

– rotary coil

Airtight openable lids

Automatic temperature and level control

The cookers are built in models of different sizes depending on the operating capacity

Automatic management of the various functions, speed, temperature, level.