MACHINES

PASTEURISERS/STERILISERS

Pasteurise or sterilise highly viscous, semi-dense and liquid products

Our pasteurisers are used for preheating and pasteurising liquid and semi-dense products, or pasteurising or sterilising heat-sensitive liquid or semi-dense products, or pasteurising or sterilising very viscous, semi-dense and liquid products

The assembly includes:

- the system for the preparation and circulation of superheated water

- the cold water supply valves, the tubular resting tank

- process piping with valves and accessories for use

- the electrical control panel with electronic equipment

- PLC and touch-screen panel, for controlling variables and managing work cycles.

The support and assembly platform are made of stainless steel and the footboard is made of fibreglass grilles.

The heat exchangers and service accessories are sized according to the required production capacity and the type of product to be processed.

PLATE PASTEURISER STERILISER

High-efficiency pasteurisation or sterilisation of heat-sensitive liquid or semi-dense products and heat recovery

These heat exchangers are characterised by high thermal efficiency and the possibility of product-product heat recovery, which may be significant depending on the temperatures involved.

The plates are sourced from the best manufacturers in the world and are assembled on a skid platform with all the equipment necessary for the operation of the system.

The heat exchangers are generally composed of three or more sections, one for heat recovery, one for superheated water heating and finally one or two cold water cooling sections.

High efficiency and thermal recovery

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer and various production capacities

QUALITY

Sized to preserve the organoleptic properties of the processed product as much as possible

COMPACT

The skid-mounted construction keeps the entire system and accessories on compact platforms

ENERGY SAVING

Exploits the residual thermal energy to reduce energy consumption

SAFETY

Our pasteurisers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking

PED-certified pressure equipment

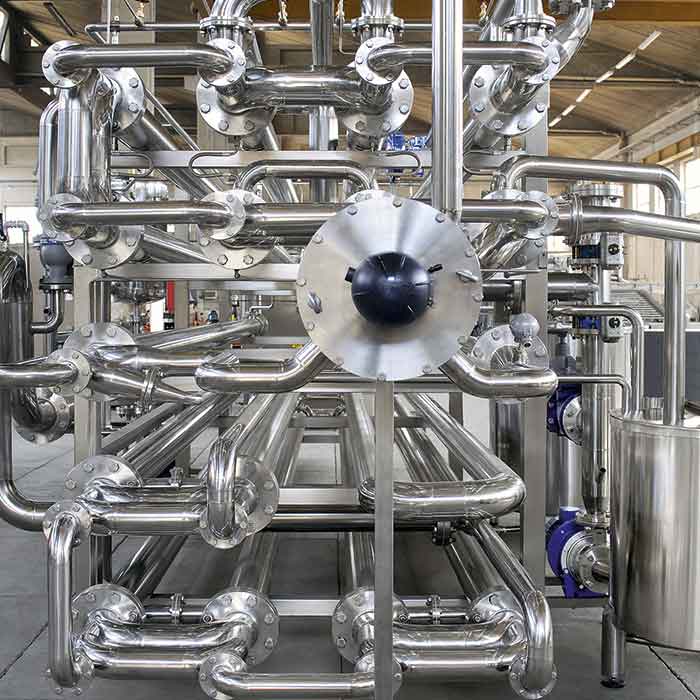

TUBE-IN-TUBE PASTEURISER STERILISER

Pasteurise or sterilise highly viscous, semi-dense and liquid products, for small and large operating capacities

Pasteurisers and sterilisers suitable for treating any type of food product, with or without pieces, concentrates, creams, purées, sauces, ketchup, tomato purée, tomato and fruit cubes, juices and nectars.

Composed of four concentric tube modules, of the size and number suited to the nature and required capacity of the product.

The range includes six different models of "Tris" heat exchanger modules, as well as three models of "Single tube" lined tube heat exchangers for products with pieces.

All the machines consist of a monoblock, with or without skid platform, and are made in AISI 304 stainless steel while the wet parts are in AISI316.

It is composed of three heat exchange sections in addition to the set of heat-retaining pipes.

The unit is complete with s superheated water preparation and circulation system, using a tube bundle and centrifugal pump, service equipment for the cooling section, including the device for washing the surfaces wetted by the cooling water.

The cooling pipes are equipped with steam barriers fed in series and controlled by a Pt100 probe.

Each module is composed of four concentric pipes forming three chambers in which the exchange water flows in the outer one and the inner one, while the Product runs in the intermediate one.

They are equipped with special flanges with O-Ring gasket and barrier steam chamber.

The modules can be opened for inspection and connected in pairs, by 180° curves flanged on one side and welded on the other side.

All surfaces in contact with the product are mirror-polished.

The product pipes are in AISI 316 and are equipped with the devices provided for the control of the various operating phases, C.I.P. sterilisation and production washing.

A electrical cabinet controls the motors and the management and control of the variables, and the various cycles, by means of a PLC and a touch-screen panel.

Small and large operating capacities

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer and various production capacities

QUALITY

Sized to preserve the organoleptic properties of the processed product as much as possible

COMPACT

The skid-mounted construction keeps the entire system and accessories on compact platforms

ENERGY SAVING

Exploits the residual thermal energy to reduce energy consumption

SAFETY

Our pasteurisers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking

PED-certified pressure equipment

TUBE BUNDLE PASTEURISER

The tube bundle pasteuriser is used for preheating and pasteurising liquid and semi-dense products for small and medium-sized operating capacities.

Made in AISI 304/316 stainless steel.

Composed of vertical modules operating in series and heated by forced-circulation superheated water from a centrifugal pump.

The water heating can be by direct steam injection by means of a special multi-jet water/steam mixer or with a dedicated tube bundle.

Equipped with all the electronic equipment necessary for the control and management of the process and safety devices provided for by directives.

The machine is sized and assembled according to the specifications required by the customer, depending on the production capacity and the rheological characteristics of the product to be processed.

Assembly as needed

ADVANTAGES AND SPECIFIC FEATURES

MODULARITY

They are designed according to the specific requests of the customer

QUALITY

Sized to preserve the organoleptic properties of the processed product as much as possible

COMPACT

The vertical arrangement of the heat exchangers keeps the system extremely compact

SAFETY

Our pasteurisers are equipped with all the systems necessary to comply with the safety requirements required by European directives and comply with the CE marking

PED-certified pressure equipment